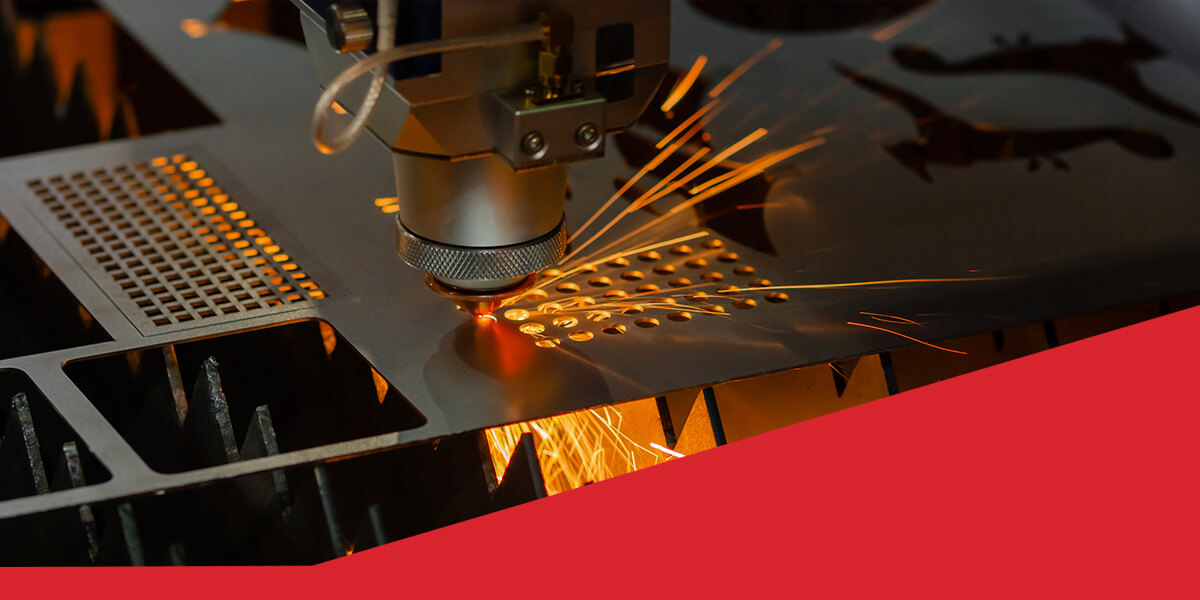

If you're in charge of keeping your production floor running, then you know how important your laser cutting machine is — when it's down, it can affect the whole operation. Understanding how to maintain a laser cutting machine will help you reduce downtime, improve cut quality and protect your bottom line.

Why Laser Cutting Maintenance Matters

Laser cutting machines rely on precise alignment, cooling systems, clean optics and airflow to function correctly. If you neglect any of these components, you'll likely experience a few different maintenance issues, such as:

- Poor cut quality: Dirty optics, misalignment or worn nozzles can lead to incomplete cuts and inconsistent performance.

- Unexpected downtime: Mechanical failures like broken belts or clogged filters can shut down production with little warning.

- Overheating and equipment damage: Insufficient coolant levels or blocked airflow can cause thermal damage to the laser head and internal components.

- Increase in material waste: Inaccurate cuts result in higher wasted raw materials and more rework.

- Higher operating costs: Neglecting maintenance can lead to more frequent part replacements and increased energy consumption because of inefficient performance.

- Fire and safety hazards: Accumulated debris, flammable residue and blocked ventilation systems significantly increase the risk of fire.

- Shortened machine lifespan: Premature wear on critical components reduces the overall service life of the machine and can accelerate capital expenses.

Benefits of Routine Laser Cutting System Maintenance

Laser cutting machine maintenance helps you achieve significant benefits as a company:

- Maximize uptime: Fewer interruptions mean higher productivity.

- Extend machine lifespan: Treat your equipment well, and it will last longer.

- Improve cutting quality: Clean optics and calibrated systems mean better results.

- Reduce repair costs: Early detection results in less expensive fixes.

- Boost operator safety: Well-maintained machines are safer for your crew.

Maintaining a Laser Cutting Machine

Laser cutting machines are complex systems. To function properly, they rely on perfectly aligned optics, stable cooling systems, high-powered lasers and clean mechanical components. When one of these elements goes unchecked, the whole system can suffer. Your team can conduct daily, weekly and monthly maintenance tasks to keep your laser cutting machine in top condition.

Daily Maintenance Tasks

Let's start with what you should be doing every single day to help keep your machine running smoothly:

- Clean the optics: Wipe down lenses and mirrors with the appropriate cleaning solution. Never touch optics with your bare hands.

- Empty the scrap tray: A cluttered tray affects airflow and can interfere with cut depth.

- Check cooling systems: Low coolant or a struggling chiller can lead to overheating and automatic shutdowns. Look for leaks and ensure water circulates properly through the laser head.

- Inspect the nozzle and gas lines: Ensure the assist gas flows properly. A worn or blocked nozzle can lead to inconsistent cuts, overheating and material waste.

- Wipe the machine exterior: A clean exterior reduces the risk of dust entering sensitive internal areas.

Weekly Maintenance Tasks

Once a week, you'll want to set aside extra time for these essential tasks:

- Lubricate moving parts: Generally, linear bearings and drive systems need consistent lubrication with approved greases or oils. Check the manufacturer's recommendations for specific guidance.

- Inspect the beam path: Use alignment tools or burn paper to check the laser's path through each mirror. Misalignments can reduce power and lead to jagged edges. This check is especially critical for CO2 systems.

- Check nozzle condition: Damaged or dirty nozzles can impact cut quality and cause flare-ups.

- Review software logs: If your system is throwing errors, don't ignore them. Many modern systems have diagnostic tools built in, so use them. If something's been flagged more than once, it's worth investigating.

Monthly Maintenance Tasks

These jobs can be scheduled into your monthly shop calendar. They take a bit more time but play a big role in preventing long-term wear.

- Clean exhaust and filters: These systems need to be kept clear to prevent residue buildup and maintain air quality.

- Examine belts and pulleys: Check for signs of slack or cracking and adjust or replace as needed.

- Inspect electrical connections: Loose wires or worn contacts can lead to shorts or system failures.

- Run a performance test: Evaluate cutting precision and speed compared to baseline values.

Annual Maintenance and Professional Servicing

Even with consistent daily, weekly and monthly upkeep, some tasks are best handled by professionals. Annual maintenance is an essential component to add to your laser cutting machine maintenance checklist because it goes deeper than routine checks. It's about recalibrating your system, catching wear that's not visible during regular inspections and ensuring everything performs as it should.

During an annual inspection, a qualified technician will typically:

- Inspect internal components that don't get regular attention, such as power supplies and wiring.

- Test and recalibrate beam alignment across the entire cutting area to ensure consistent output. Minor shifts over time, especially in large-format jobs, can reduce precision.

- Check laser power output using specialized tools.

- Replace aging consumables that may still be functional but are nearing the end of their life, such as filters, belts and optical components. Proactive replacement here prevents breakdowns in mid-production.

- Review firmware and software for needed updates. These updates can improve system efficiency, fix unknown bugs and introduce helpful new features.

How to Identify Early Warning Signs

Even with a solid maintenance schedule in place, issues can still develop over time. The key is knowing what to look out for. Here are some examples:

- Changes in cut quality: If cuts start looking inconsistent, edges are rougher than usual or you're not getting full penetration through the material, something is likely wrong.

- Increased spark or flare-ups: More visible sparks than normal often point to nozzle damage or improper gas flow.

- Unusual sounds during operation: Grinding, knocking or high-pitched whines can indicate mechanical wear.

- Error codes or frequent stops: If the machine's control panel shows fault codes more often, it's time to investigate.

- Temperature irregularities: If the machine is running hotter than usual, check coolant levels and inspect for blockages.

- Inconsistent gas pressure: Fluctuating or weak gas flow can affect cut quality and signal a problem.

Partner With Alternative Parts, Inc. for Smarter Maintenance

Laser cutting machines are built for precision and performance, but only if they're maintained with the same level of care. When you stay on top of your maintenance routine and respond early to warning signs, you reduce downtime, protect your equipment and keep your operation running smoothly.

Maintaining a laser cutting machine is about having the right parts on hand and the proper support behind you. That's where Alternative Parts, Inc. (API) steps in.

We do more than sell replacement components — we help owners and operators of industrial laser cutting machines solve problems quickly and return to work with minimal disruptions. Whether you need help identifying a part, understanding why something keeps failing or scheduling on-site service, our team is ready to assist.

With a full range of original equipment manufacturer parts, responsive service and expert guidance, API is ready to help you stay efficient and prepared. Contact us today to learn how we can help you keep your operation running smoothly.

Linked Sources: